Name : Mahabir Chowbey

District & State : Purulia, West Bengal

Category : Utility

Award : National

Award Function : 3rd National Grassroots Innovation Awards

Award Year : 2005

Innovation Description

Mahabir Choubey (48) hails from Kashipur village in Purulia, West Bengal. His family consists of his wife, two daughters and a son. Presently he earns his living from a small business of courier franchisee and battery charging. Inspite of financial hardships, he has tried to give proper education to his children- his son is doing his B-Tech in Computer Science , his eldest daughter has completed her Physics honours and his youngest daughter is in the 11th standard. He remembers that at times circumstances were so strained that he had to sell all their jewellery and mortgage their land to make ends meet. His monthly income is Rs.1600-2000.

Mahabir Choubey (48) hails from Kashipur village in Purulia, West Bengal. His family consists of his wife, two daughters and a son. Presently he earns his living from a small business of courier franchisee and battery charging. Inspite of financial hardships, he has tried to give proper education to his children- his son is doing his B-Tech in Computer Science , his eldest daughter has completed her Physics honours and his youngest daughter is in the 11th standard. He remembers that at times circumstances were so strained that he had to sell all their jewellery and mortgage their land to make ends meet. His monthly income is Rs.1600-2000.

Genesis

Choubey’s innovation is based on the elasticity of materials- wood in this case. His logic is that when a screw is driven into wood, some wood is pushed away which tends to return to its original state. This exerts an opposite force on the screw (though weak) due to which the screw gets loosened over time. This phenomenon is accentuated if the wood is in a state of constant vibration and therefore the screw sometimes comes out automatically. To mitigate this ‘natural’ tendency, Choubey thought of making some grooves in the screw. This would allow some wood to occupy this space thereby reducing the opposite force and rendering a locking mechanism at the place of the grooves. Hence Choubey felt that the screw should be made with both threads and grooves, so that it will have increased grip due to the threads that cut into the wood and the wood in the grooves would provide extra locking.

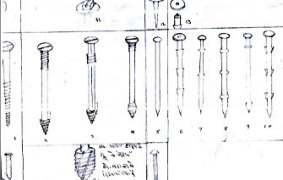

The innovation is a wooden screw, which has combined the features of the conventional wooden screw (threaded conical front) and metal stud (constant pitch intermediate thread). The novel screw thus comprises a head portion provided integrally with the body portion. The screw is tapered at the tip and the remaining portion possesses constant diametrical threaded pitch like the conventional metal screw/stud. The thread portion has a combination of common threads being provided on the body portion along with special kind of threads being provided at an inclination with respect to the common thread. There is also an unthreaded portion along the constant diametric length like the stud used in engine head. The heads are slotted so that they can be driven by a screw driver. This screw has an advantage of cutting its own threads when it is being screwed in for fastening purpose. Due to the use of Seller’s /ACME type of threads, stress concentration becomes less and thus reduces subsequent failure (cracks) that occurs in the wood.

Advantages

The tapered and threaded head of this screw facilitates easy movement into the work piece. Less effort is required to drive it in. Wood would also not crack while drilling (driving) in the screw. The screw will not become loose after some time, as it is broader at its tip and the cross sectional wedges around the screw (3-4) give it a better locking mechanism or grip. Even if the head breaks, the screw can be pulled out due to modified head configuration. A combination of inclined thread provides better gripping capacity and it requires no tapping unlike conventional metal screw.

Relevance

Screws are being used almost in all kinds of furniture and other items made of wood, steel, aluminium etc. The most commonly used screw comprises two portions namely head portion and body/length portion. The body/length portion has neck, thread and point portions. The head portion comprises a channel at the top surface thereof for facilitating the screwing and unscrewing of the screw into/from the furniture with the help of the screw driver. The thread portion is provided to facilitate the insertion and exit of the screw into and from the material of the item. The point portion facilitates the easy insertion into the material of the item.

But the main disadvantages of the conventional screw are that it has got very little gripping property and comes out easily from the item in which it has been used, after sometime. Considerable force or pressure is required to drive the screw into any wooden structure. There is also greater possibility of the wood cracking around the place where the screw has been driven into the wooden structure. Sometimes the groove in the head of the screw breaks and it becomes impossible to fix a screw driver on the screw. This becomes even more irksome if the head of the screw breaks after it has been driven into the wood and then it becomes almost impossible to pull out the screw again. The novel screw conceptualised by Choubey is intended to overcome the problems which occur in conventional wooden screws. NIF has filed a patent application on his behalf for the novel screw and the number is 06/KOL/2004, 06/01/2004. NIF has also sanctioned him a sum of Rs.4, 366 from the Micro Venture Innovation Fund for prototype development and testing of the Novel Wooden screw.

Test results

Pull out test on this novel screw by Choubey was carried out by the Applied Mechanics Department, L.D. College of Engineering, Ahmedabad and the results show that there is an improvement in this screw in terms of holding capacity (therefore there is an observed increment in pullout load) as compared to the M.S. Normal screw.

This is what. Prof S.B.Soni (Retd) from L.D. Engineering College has to say about the innovative screw:

“Cracks normally occur due to stress concentration. This kind of screw may help to reduce cracks. The groove may help to tighten the wooden piece i.e. better gripping is possible.”

A plethora of ideas…

Mahabir Choubey is a man of action with a very progressive and innovative mind. Though he has studied only till the seventh standard, he has a reasonable understanding of some of the scientific principles and technological developments. From childhood he refused to accept imposed concepts and rules unquestioningly. He had developed new ideas and fabricated some models/prototypes in the past-including an analog Robot (this analog automated device he developed towards the end of the 70s/early 80s when transistors and ICs were not much in use). He also experimented with running two-wheelers by Hydrogen in the mid 80s (definitely ahead of time), but couldn’t pursue it further for various reasons. A serial innovator, Choubey’s mind is always buzzing with ideas and that too in diverse fields. A number of his ideas are detailed below:

Smokeless Oven

The innovator has developed a smokeless oven with a narrow neck made of three units joined together whereby the smoke is led out of an exhaust chute without discomfiture to the user. Inlet holes for air flow and subsequent cleaning of soot and deposits are located at the bottom and the heat is captured effectively in the belly shaped pot interior. A top component with a narrow neck for guiding the heat and reducing the smoke along with a bottom stopper for the stove is provided. Locally available clay is used and the exhaust could be a tin/metal pipe. The basic unit would cost Rs 12 as per the innovator. This device would reduce the problem of smoke entering the eyes and pollution and would thus make a significant difference to the health and comfort of women who generally use the stove.

A method of minimising friction in bearings

In conventional ball bearings steel balls are placed in the annular space between two annular metal rings. The balls are kept separated from each other and held in place by thin metal foil, called separator. During motion considerable friction occurs between metallic foil and the balls. This raises the temperature of the bearing beyond the desired limit and it increases the requirement of lubrication. Choubey’s idea is to introduce small size rollers in place of the conventional separators. He feels that this will reduce friction as well as lubrication requirement due to point contact between roller and balls.

An indigenous recordable stethoscope

Concerned about the fact that medical facilities are not always easily available in rural areas, Choubey got the idea of making a local stethoscope –using a plastic/metal funnel with a condenser microphone installed inside it. That microphone socket is attached to a tape recorder and the heart beat is recorded in the tape recorder in a cassette. This cassette can be taken to the doctor and patient doesn’t need to be moved. He feels that even an ECG can be taken by connecting this recorded sound to the relevant machine.

Improved bricks

Choubey had noticed that the bricks, used to make houses in his area, are made from yellow soil with which sand and water are mixed. These bricks are dried and then baked in a furnace. But it has been observed that these bricks are not very strong and easily disintegrate. So his idea is that if soda (Na2CO3) is mixed with the raw material, the bricks will become stronger and long-lasting. He thought of this idea by looking at the method of making glass.

Spreading the innovative spirit…

Such is his passion for rationality, creativity and scientific temper that he spearheaded a sort of youth science movement in his area –mainly with his own money, despite his limited income. The main objective of this Vigyan manch is to popularise science and create awareness about science among the masses. This movement he has started is also involved in recognising young talents (in diverse fields like science, arts, sports and so on), challenging age-old superstitions prevalent in the region as well as preserving local history and culture. He had developed a photo- archive of Jain relics and some fossils too and some of the findings were endorsed by relevant experts. Choubey feels, “In villages there is no internet, modern facilities etc ie why people with ideas cannot go further” and that has inspired him to do his bit in the service of society. His work has been featured in various newspapers such as Ananda Bazaar Patrika, Purulia Samachar etc

Choubey also has a suggestion there should be a fund which can help innovators when they are in dire financial crisis (not necessarily just for innovations, but for other livelihood emergencies). He felt from his own experience that such a support system is very much needed for the survival of innovators.