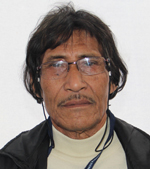

Name : M Manihar Sharma

District & State : Imphal, Manipur

Category : Engineering

Award : National

Award Function : 8th National Grassroots Innovation Awards

Award Year : 2015

Price : Rs. 60000/- (Ex-factory price + packaging). The price does not include transportation costs, taxes, etc.

Innovator Profile

Innovation Description

Technical Specification

Salient Features

Scout: Direct

Manihar Sharma (65) is a mechanicand a serial innovator who has come up with a number of useful innovations like a handy incense stick making machine, an innovative dryer, automatic pump operation system for overhead tanks, etc. To simplify the tedious task of reeling silk traditionally, Manihar has come up with a solar operated machine, which can simultaneously perform reeling and spinning of different types of silk.

Background

After working as an auto rickshaw driver, running a small restaurant, serving as an assistant to his doctor friend, Manihar Sharma has been a full time innovator for some time now. Economic hardship and lack of support did not deter or hamper his innate creativity. For his lack of practicality, the

society and his own family mockingly brand him as “numikadoba” (the man who would go to the Sun).

The Early Beginning

Manihar’s aunt brought him up as he lost his mother when he was just eight years of age. After matriculation, he abandoned his studies because of financial problems and started working as a mechanic in a small local workshop. Giving shape to his imagination, he made toys and other small gadgets from the left over parts in the workshop. With his perseverance he soon mastered all the nuances of repair and maintenance of small light vehicles and other engines. His constant source of inspiration has been his late mechanic teacher, who used to repair or modify complicated machines without needing any sophisticated tools and equipment. The backbone of his innovative spirit has been the informal yet logical and practical mechanical tips shared by his mentor.

While he tinkered day and night, the availability of mechanical and electrical parts needed by him in the local market became a problem. They could only be brought in bulk, either from Kolkata or Guwahati. The inability to buy expensive parts from the markets outside the state, forced him to manufacture those plastic parts himself. So this frugal innovator enrolled for a three months course on plastic molding techniques at Central Institute of Plastic Engineering and Technology (CIPET), at the age of 50+. And he was the only trainee, among the hundreds, who actually made use of the technology. The obsession to do the things perfectly made him first practice the art of manual molding of plastic for years. His hard work and sheer perseverance makes even the CIPET send him job works sometimes.

After having gone through different phases in life which molded his personality and gave impetus to his aptitude for innovating, he became a full time prolific innovator. His most recent innovation is the ‘solar multi muga reeling cum spinning machine’.

Genesis

Conventionally, in Imphal, mostly women are involved in silk reeling. Manihar realized how difficult it was for the women to judiciously balance the available time between household activities and silk reeling. His desire to help reduce the drudgery involved in the work, made him want to develop an automated silk reeling system, which did not require constant monitoring. This would help the women to simultaneously carry out their household work and silk reeling task with optimum output. Since all places in Manipur do not have access to electricity, he thought about using solar unit as source of energy. His machine is sosimple that an untrained person can operate it.

http://nif.org.in/innovation/solar-multi-muga-reeling-cum-spinning-machine/774