Name : Kailash Srivastava

District & State : Narsinghpur, Madhya Pradesh

Category : Engineering

Award : Consolation

Award Function : 3rd National Grassroots Innovation Awards

Award Year : 2005

Innovation Description

Kailash Srivastava (32), hails from a remotely located village, Dobhi in Tendukheda Tehsil of Narsinghpur district of Madhya Pradesh. He lives with his wife, son and mother. His only source of income is his repair shop. He plays ‘tabla’ and this interest has guided him to develop an automatic note generating machine (similar to harmonium).

“He doesn’t give up on anything once he has decided and does everything to achieve success”.

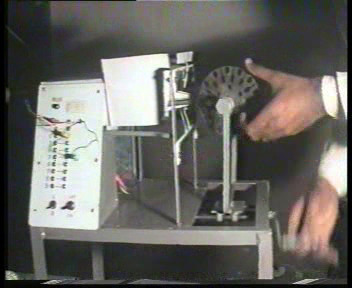

So declares the mother of Kailash Srivastava with pride in her son who has developed a cost- effective multi-purpose and precise electronic motor coil winding machine that can be used for a wide range of winding applications for stators and transformers, fans, coolers, pumps, as well as grinders and mixers.

So declares the mother of Kailash Srivastava with pride in her son who has developed a cost- effective multi-purpose and precise electronic motor coil winding machine that can be used for a wide range of winding applications for stators and transformers, fans, coolers, pumps, as well as grinders and mixers.

Genesis

Kailash explains that the amount of work that he received in his shop was gradually increasing and it was becoming increasingly difficult for him to handle such a huge workload. He could also not afford to take the help of heavy winding machines available in the market at that time as the cost was too high. This forced him to search for an alternative which would be portable, handy, cost effective and efficient in functioning.

He didn’t have any suitable place to develop his prototype and therefore selected his shop as a laboratory and started his dream project. He took nearly three years to develop a working model of the innovation mainly as he had to face a lot of procurement problems during the construction of the innovation. As Dobhi is a remote village, he had to get all the working components and processing jobs done from nearby Tendukheda and Narsinghpur and had to go to Jabalpur to purchase simple electronic items like transistors, diodes, and capacitors. This was a costly as well as time taking process. To overcome this, Kailash used locally available materials like pipes of hand pumps, gaskets of pressure cooker (as conveyor belt) and wooden blocks where possible.

His mother constantly supported him throughout the process of innovation. She allowed him to carry on his experiments in spite of his father’s poor health, especially in the face of criticism from others that Kailash should be concentrating on his family and not waste time. He was helped a lot by Mr. Suryakant Divagainya from the same village in preparing all the technical documentation of the product as well as for the correspondence with NIF and other institutions. He also acknowledges the help provided by Mr. Rajendra Kumar Jain, the upsarpanch of the village in activities like body design, CD recording etc.

He has been using the machine for the last three years providing full satisfaction to his customers. The innovator declares that the machine has helped him improve his productivity and efficiency. On an average, he has repaired 700-800 equipments over the past year. Before the use of the machine, he charged Rs.200 per fan repair, but now he merely charges Rs.100 per fan repair. The consumers have also benefited.

The basic electronic circuitry comprises of the following components namely an AC transformer (9V, 500 mA), DC Regulator (6V),Counting Oscillator IC, Auto stop IC, Counter ICs(3), Seven segment display, 6V relay, 4007 Diodes(14), 7 V Zener diodes(14), Capacitors, Resistances, Transistors and a 6V, 750 Ma battery

There is an iron frame fitted with screws to mount the stator/ other equipment for winding. The coil required for winding has to be kept separate and wound once around the assembly for starting. There is a screw for adjusting the tightness with which the coil has to be wound. The basic outer assembly comprises of a pulley system aided by shafts and small tunnels which is instrumental in the flow of the winding wire during the process of winding. There is a facility to check the centre alignment of the stator with the centre mouthpiece of a die and lock it. Besides, there is an arrangement for the horizontal movement of the frame on which the stator has to be mounted for centre alignment aided by a movable shaft that has to be properly lubricated for easy movement.

There is a push button to start the process. In addition there are two two-way switches. One is an ON/OFF switch, which starts and shuts down the machine. Another switch is used for left- right alignment of the rotation of the coil. Then the equipment to be mounted is prepared by inserting paper attachments in the stator holes to avoid direct contact of the stator with the winding wire. After that the equipment is mounted, checked for centre alignment and locked. One turn of winding wire is manually wound around one of the stator holes and is prepared for action. The number of turns required is then set by the socket pin arrangement on the front of the cabinet. And the process is started by pushing the ON switch.

The front side of the cabinet has three columns having 22 sockets of 10, 10 and 2 sockets respectively. The number of turns required is input at the front of the cabinet by the socket pin arrangement. This information is conveyed to the three counter ICs. One IC controls the hundred’s count and is calibrated from 0-9. The second one controls the tens count and is also calibrated from 0-9. The third column represents the unit’s place and is calibrated for two digits 0 and 5. For example, to make 360 turns, insert pin 1 (which is attached further to the electronic circuitry) to place 3 in the first column, pin 2 to place 6 in the second column and pin 3 to place 0 in the 3rd column. A digital display connected to the three counting ICs and the counting oscillator displays the number of turns getting wound. One counting oscillator IC keeps a count of the number of turns wound. Once, the requisite number of turns are met, the three counter ICs send a signal to the Auto stop IC which activates a relay and stops the machine.

The process of winding is powered by a 220 V A.C. electric motor and four wheel bearings. The device winds the exact number of coils and stops at the very instant the number of turns are reached. Then the position of the left-right switch is altered and the process is repeated till the entire winding of the stator is completed. The entire circuitry is powered by a 6V battery. Power supply is received from the 220V A.C. mains lead and is converted to a desirable input voltage by a 9V transformer. A 6V D.C. regulator regulates it.

Advantages

This device works effectively for all type of domestic motors like fan motors (i.e. ceiling, table and cooler), transformers, mixer-grinder etc. It has the facility to restart from the same count where it stopped and it works at a speed of 600 rounds per minute. This device takes up to 30-35 minutes to do the binding of a ceiling fan coil. All the dyes are made of fibre which annuls any possibility of scratches in the wires and there is no risk of the wires snagging and breaking. It has an electronic counting meter which has auto stop facility. It has a user-friendly operating interface which any untrained person can operate. It also has a memory circuit in which it is possible to set the number of turns required before hand and which automatically stops after completion of the desired number of rounds/turns. The maintenance cost is very low and the device consumes less electricity i.e., hardly around 70-75 watts and can be operated by inverter also. It works on 150 Volts AC to 230 Volts AC. The quality of the electronic coils made with this machine is very high, because of which the electrical equipment using these coils function efficiently and for a long time. All the parts used in it are easily available in the market. It is shock proof and doesn’t create much noise or any waste and therefore can be kept at any corner of a small room. The simple push button systems, automatic operation and smooth coil loading and unloading stations means women can also easily operate this machine. It is equally useful for large factories as well as small individual binders. This innovation also has great social relevance. It has the potential to free thousands of child labourers since in almost every motor winding workshop; the task of winding is done by child labourers.

An affordable alternative …

Burning-out of the coil of electric fans is very common in rural as well as semi-urban areas due to erratic power supply and fluctuating voltage. These problems occur frequently in locally made fans which are widely used in rural areas. Coil making is an arduous and time taking process. If done manually it takes 8-12 hours per motor. Generally it is done by children who work as assistants with the local electricians. It needs a lot of concentration in counting the number of coils, which run into hundreds. Finger tips get bruised by continuous coiling. In addition the motor winding machine along with dyes of popular brands cost around Rs 22,000 to Rs 28,000 which is beyond the purchasing power of a rural electrician whose annual turnover hardly reaches Rs.50, 000. The automatic motor coil winding machine of Kailash Srivastava addresses all these problems as compared to other machines, it is cheaper at Rs. 5000, with less maintenance cost and more functions and can bind coils of many types in a short while, at the same time ensuring high quality output. As this device reduces drudgery and imprecision of manual coil winding operation which is slow, tedious and error prone, this could be a source of income for unemployed people who could start a small business equipped with this machine. There is wide scope of diffusion of this device in the coil and motor winding industry which is a cottage industry in rural and urban areas. Market survey reveals availability of similar machines but their selling price is much higher than the one developed by the innovator.

A resounding success… Presently Kailash has been getting 700-800 motors for coiling on an annual basis for the last couple of years. His customers are electricians (who bring jobs in bulk) whom he charges Rs.100 per motor and earns Rs. 60-75 per piece. The electricians charge Rs 150 from the end users and earn about Rs. 50. A lot of time is saved and customers are happy with the timely service. This machine is currently catering to the needs of 40 odd adjoining villages. Kailash also got a chance to display this auto electronic binder at the National Physical Laboratory, New Delhi on 19 February 2004 where it was much acclaimed. A report on the innovation has been published in the laboratory’s Smarika .The machine was also demonstrated to thousands of people in the Varman Mela. It has also been certified by the District Industry Office, Narsinghpur. Future prospects… Kailash has also demonstrated the machine to wholesalers of electric goods who have shown deep interest in the same and demanded samples for further demonstration. But according to Kailash, development of another piece would take six months because facilities are not available in the village. He would need a lathe and wielding machine to build the body of the machine. A proper lab is also needed for the same. Apart from this he would have to set aside his work in the shop and concentrate on this device. If he closes his shop for such a long time, he would incur economic losses as well as lose many of his regular customers. Hence currently he is interested in transferring the technology to a third party who will help in developing the product and commercializing it. On the other hand, according to Kailash, if the assembly work is distributed among six workmen (cutter, welder, dye maker, electrician, finishing and painting expert, helper), then it is possible to assemble two to three machines in a day. He goes on to explain that with an initial outlay of five to six lakh rupees, it is possible to manufacture and sell this machine in bulk. The material and labour cost of a machine according to his estimate is only Rs. 2000. So if it is sold at Rs.5000, it will be possible to recover the initial investment and also earn a decent profit. Ideally he would like to start a business out of this innovation but this is provided he gets adequate technical and financial assistance. NIF has sanctioned Kailash Srivastava a sum of Rs.35, 000 from the Micro Venture Innovation Fund for prototype development for market research of the Automatic Motor Coil Winding Machine. A passion for electronics… During his school days itself, Kailash had an inclination towards electronics and electrical devices. After passing his senior secondary examination (12th standard) in 1989, along with a few of his friends, he planned to undergo training at Lutiya T.V training Centre, Raipur. But his parents didn’t give him permission as his mother was unwilling to allow him to go to such a far place. But undeterred, Kailash fled away from home with Rs. 5000 in cash. He had obtained this money by mortgaging his mother’s ornaments with a moneylender and undertook a TV training course in both B & W and Colour Television from Lutiya TV training centre. Now he owns an electrical and electronics repair shop in Dobhi, adjacent to his house, where he repairs ceiling and table fans, small to medium sized electrical motors, transformers (small size) and other coil winding jobs. He has been running this repair shop for the past 10 years. In addition, he also develops and repairs certain electronic circuits which find use in certain consumer electronics goods like television, radio etc. Kailash’s tryst with innovation does not end with this automatic motor coil winding machine-he is also working on the following ideas- electricity generation through weight, speciality transformer winding machine, D.C Emergency fan and an automatic musical note generating machine.

http://nif.org.in/innovation/Automatic_Motor_Winding_Machine/222